|

| November 27, 2012 | Volume 08 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Drives and controls:

Newspaper techs get lessons in troubleshooting, restarting presses

The Courier-Journal uses a state-of-the-art KBA Colora web offset press. [Photo courtesy: KBA]

The Courier-Journal, owned by the Gannett Corporation, is the single largest daily newspaper in Kentucky, with a daily circulation of 150,000 and a Sunday circulation of 250,000. The newspaper, based in Louisville, commissioned a state-of-the-art KBA Colora web offset press in 2004. "The press department was accustomed to older, manually operated equipment and they had to become familiar with new, state-of-the-art press controls and technology," says Tom Letto, production director at the Courier-Journal.

The Courier-Journal has three editions that print each night. "We used to run our full circulation on two presses and if one of these presses went down, we were losing half our production. To be more efficient, we've been running everything on one press for about two years," Letto says. "If that one press goes down, it results in 100% downtime. Any downtime now is extremely critical."

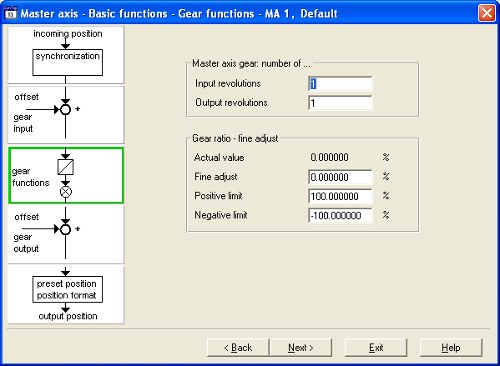

The KBA press includes a Rexroth digital intelligent drives system comprised of electronic drives, motors, and controllers using SYNAX firmware to provide Electronic Line Shaft (ELS) capabilities. Instead of a mechanical main shaft with couplings, drives, and cams, the SYNAX system uses synchronized electric drives and motors to implement the press functionality. Rexroth's Syntop software is used to interface with the electronic control system.

"Electronic Line Shafting has been around for a long time -- the benefits over mechanical presses are tried and true," says Mark Schwab, Bosch Rexroth service engineer. "At the same time, it's versatile and can integrate with all sorts of controls."

The Courier-Journal technicians received an advanced training course that covered the press' communications systems, the capability of the controls, and the information that could be accessed via Syntop software.

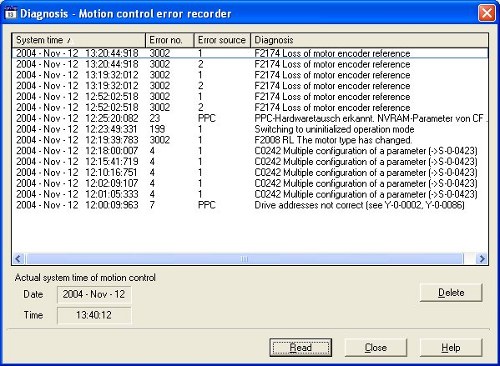

The Courier-Journal technicians use a personal computer in the building that accesses electronic control cards on the printing press, but they were not experienced with using Rexroth's Syntop software to retrieve and analyze diagnostic information from the control system. Several years after the installation, the press began to experience more frequent errors. "When our press broke down, we wouldn't have any advance warning," says Letto. "In addition, our technicians didn't have a clear indication on what areas to begin troubleshooting."

Schwab says the Rexroth system is designed to monitor a multitude of parameters throughout the press and display an array of warning and error codes when anomalies in the overall application are identified, such as a loose cable, bad grounding point, improper parameter setting, temperature, mechanical jam, or incoming power issue. While these warnings and errors do not necessarily indicate that the Rexroth equipment or hardware is the root of the failure, they are vital in the troubleshooting process and help lead to the root cause from where the faults are being generated. Without the insight from the warning and error diagnostics to help pinpoint the root cause, technicians would often mistakenly swap out the Rexroth components, frustrating the maintenance staff and causing extended downtime.

According to Letto, the biggest problem occurred when the press lost power during a large storm in 2010. "When the press loses power, it's difficult to start back up again because of all the different integrated communication software that's involved," he says. "Things had been running quite well, considering how long it's been and how big the machine is, but when there was a problem, diagnosing it was a gray area."

"The technicians are in this tough spot where they have a press that includes a lot of equipment," says Schwab. "When something breaks down, they're under the gun because they have limited time to get this press running without knowing where to start or what to look for to troubleshoot these highly integrated systems."

During a breakdown, the standard escalation process is for Courier-Journal staff to contact the machine builder (KBA), the software vendor for the press controls (EAE), and Rexroth for technical assistance. This approach helped in solving the immediate problem to get the press back online after the power outage. However, Letto wanted an optimal solution for future preparedness where the Courier-Journal would be able to resolve the problem internally in a quick manner to improve uptime. This led to a joint effort between the Courier-Journal, KBA, and Bosch Rexroth. It was decided that the best approach would be to provide an advanced maintenance and troubleshooting class where the Courier-Journal staff would learn to use the SYNAX system and Syntop software to examine the vast array of equipment to avoid similar problems in the future. Schwab developed and implemented a comprehensive training program so the Courier-Journal maintenance staff could determine if the errors were originating with the Rexroth equipment, and, if so, how to address them.

The class lasted two days, with half the time spent in a classroom and the other half spent hands-on working with the press. The course covered the press' communication systems, the capability of the controls, and the information that could be accessed via Syntop software. Schwab provided the 10 Courier-Journal service technicians and press operators who attended the class with manuals describing the Rexroth equipment that was on the press. "We reviewed the communication that occurs between Rexroth equipment and other parts of the press. The technicians also learned to troubleshoot using Syntop software to diagnose the faults that occurred on the Rexroth equipment and how to resolve them," Schwab says.

Instead of a mechanical main shaft with couplings, drives, and cams, SYNAX system uses synchronized electronic drives and motors to implement the press functionality. Rexroth's Syntop software is used to interface with the electronic control system.

"The training not only provided knowledge most of our staff didn't have, but also trained them on using the software, so they knew what the codes meant and how to interpret what was going on," says Letto. "Before the Syntop training, we were averaging 92% on time, with 8% downtime. Since then, we've gone to being 98% on time, or only 2% downtime, with better performance overall." Because the Courier-Journal technicians now understand the error and troubleshooting codes, the staff has developed a new procedure to monitor the software weekly to check for warnings, essentially proactively preventing failures before they occur. "We keep a log and track the codes so that anyone who accesses the software can analyze them once a week. That allows us to follow up on any codes that could be a potential problem," Letto says.

"The Syntop codes give you enough general information that you can predict failures," Letto says. "Since the codes tell you where to check for a potential problem, you have advance notice or advance warning about the problem and you can start looking into it. We're seeing the problems beforehand and making the corrections before they affect us on deadline. It's had a huge impact on our overall operations. Before the training, if we went down, it affected the overall delivery of our newspaper. Now we're able to react quicker and know what's going to happen before problems arise."

Because the Courier-Journal technicians now understand the error and troubleshooting codes, the staff has developed a new procedure to monitor the software and check it once a week for warnings, effectively proactively preventing failures before they occur.

The training also improved the staff's ability to troubleshoot the system. "The training cut the troubleshooting time in half," Letto says. "So if we do have a problem, it's not as critical. In the past, when we've had problems, we would have lost more than an hour just to troubleshoot the problem, then half an hour to get a replacement part."

Letto is a board member of the KBA Users Group, which provides valuable information on best practices of successful press operation among the companies in North America who use KBA web presses. He highly recommends the training for newspapers and other companies that use machines with SYNAX firmware and Syntop software. "We're participating in a weeklong Web-based Syntop training later this year," Letto says. "Technicians at four printing sites within the Gannett Corporation will participate."

Source: Bosch Rexroth

Published November 2012

Rate this article

View our terms of use and privacy policy